Design & Installation

Resistance to Pressure

Gravity waste water drainage systems and ventilation systems generally operate without pressure. This does not exclude however , the possibility of pressure arising in the systems under specific operating conditions...

Ventilation

A drainage pipe is normally at neutral air pressure compared to the surrounding atmosphere. When a column of waste water flows through a pipe, it compresses air in the pipe, creating a positive pressure that must be released or will push back on the waste stream and downstream traps’ water seals. As the column of water passes, air must flow in behind the waste stream or negative pressure (suction) results. The extent of these pressure fluctuations is determined by the fluid volume of the waste discharge

Access to the Network

Access to the pipework must be ensured so that tests, inspections and maintenance can be performed. Access may be obtained using a short access pipe.

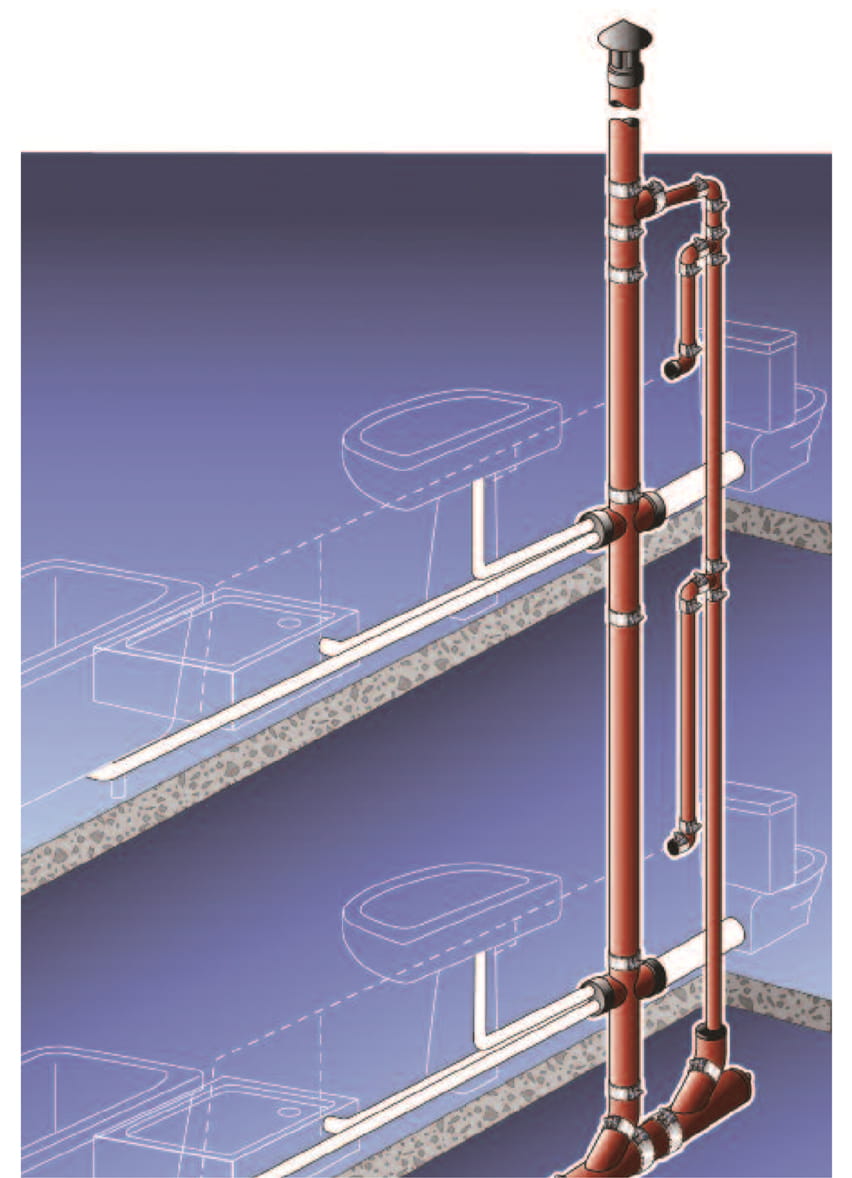

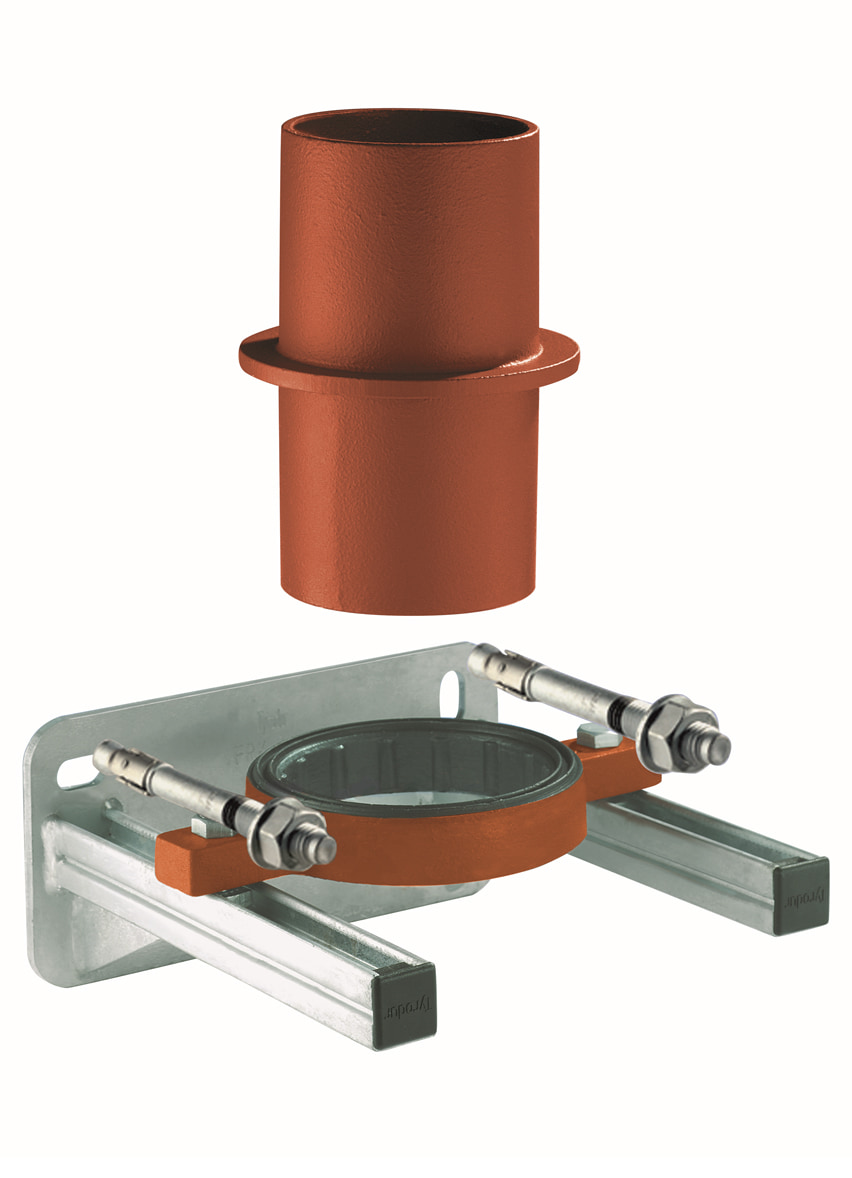

Network Supporting

For cast iron, the bracketing system is designed to only carry the weight of the pipe and its content, which makes the specifiers’ design work easier

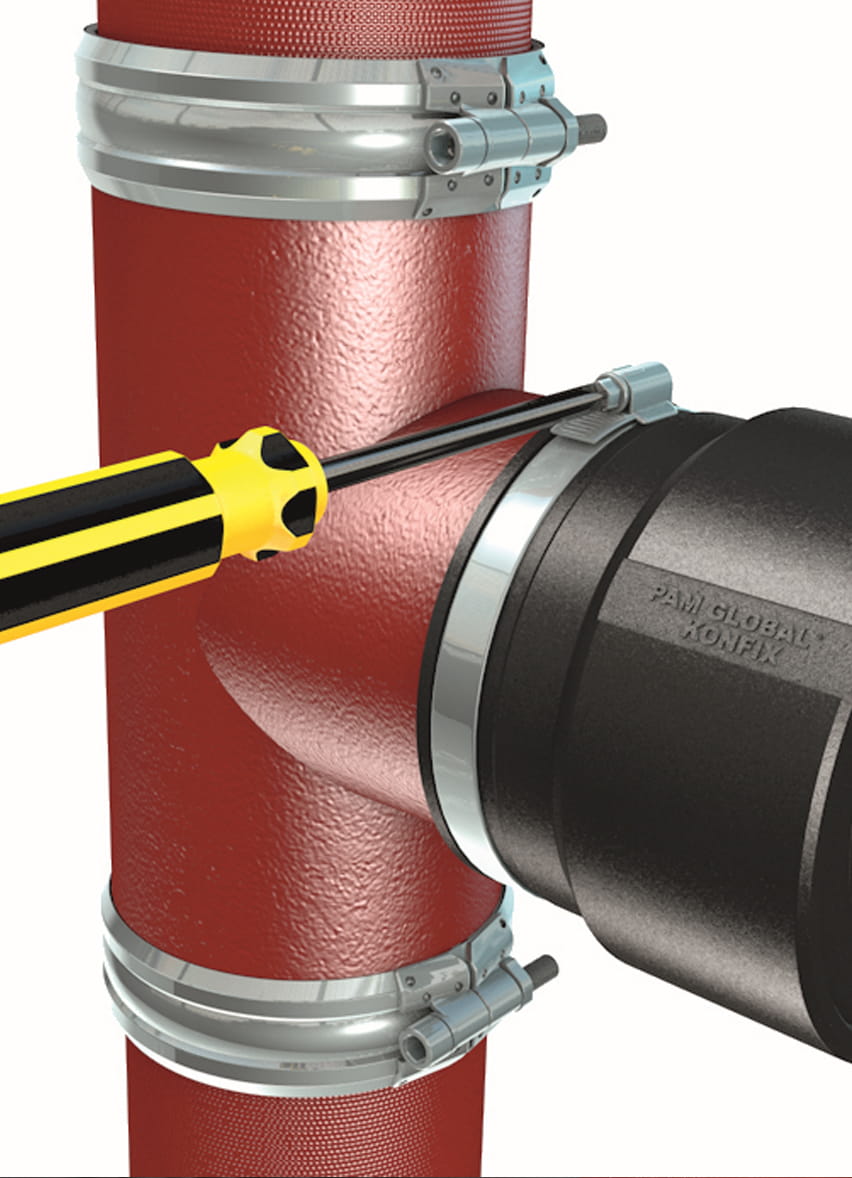

Coupling Methods

Some couplings can be assembled in two parts and others can be assembled as a single part.

Connection to other Materials

The easiest way to connect cast iron systems to other drainage materials is to use rubber connectors or plugs. Flexible couplings and stepping rings are also available to ease connections where variances in diameters have to be compensated.

Multi Waste

The multi-waste manifold simplifies waste plumbing by grouping all associated pipework from various sources such as sinks, basins, bidets, urinals and showers to one internal point above the finished floor level. The manifold will permit the connection of three 32/38mm

Buried Network

The Drain range pipes can be used in below ground applications. Buried pipes are subject to mechanical strain due to the weight of grounds and possibly wheel loading when they are laid under a circulating area.

General Installation Instructions

Cast iron pipe systems for drainage mainly consist of spigot pipes - generally supplied in 3 m length - and fittings of various shapes (bends, branches, etc.). The cast-iron pipes can be cut to length. Where pipes are cut on-site, ends shall be cut clean and square with burrs removed and then re-coated with the adequate touch-up paints EXTREM 1, or other repair products recommended by Pam Building.

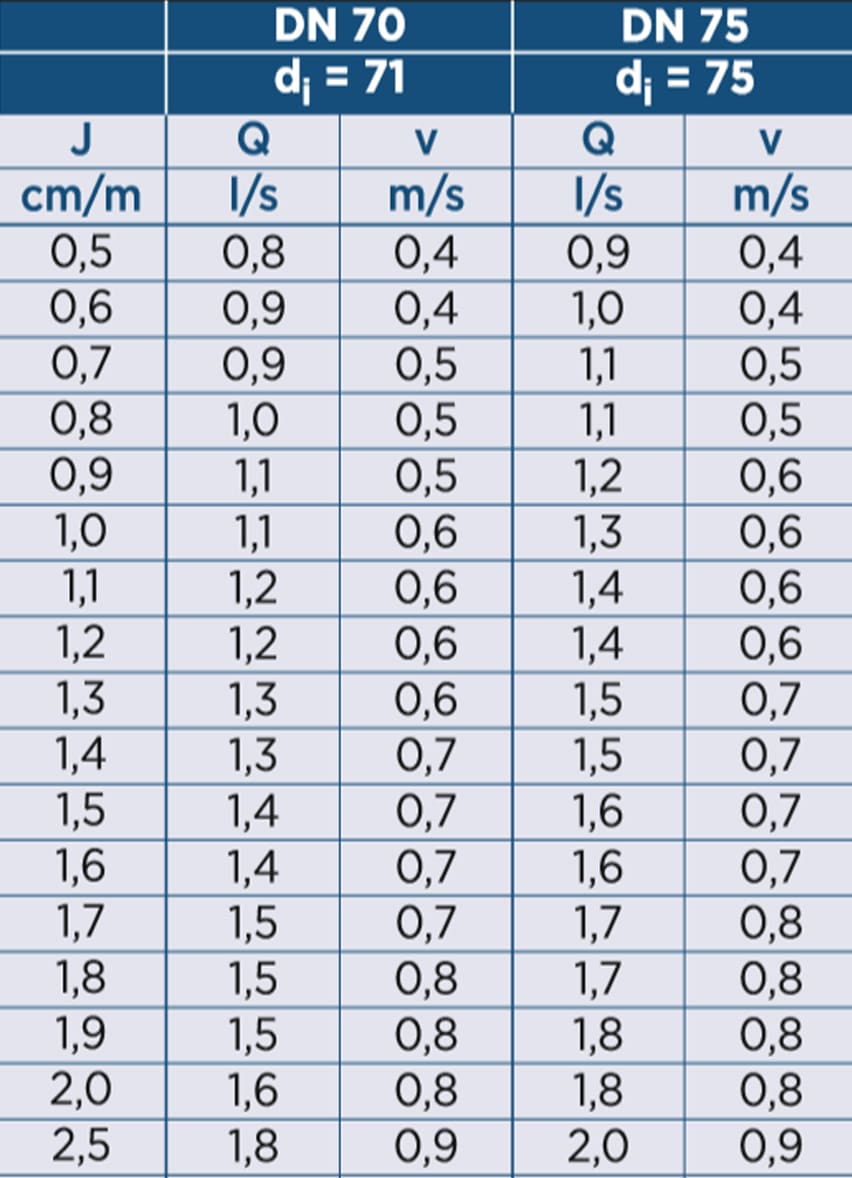

Discharge Capability

Discharge capability of Pam Building pipes according to EN 877 and DIN 19522