Pre-Assembly

Saving You More Than Time

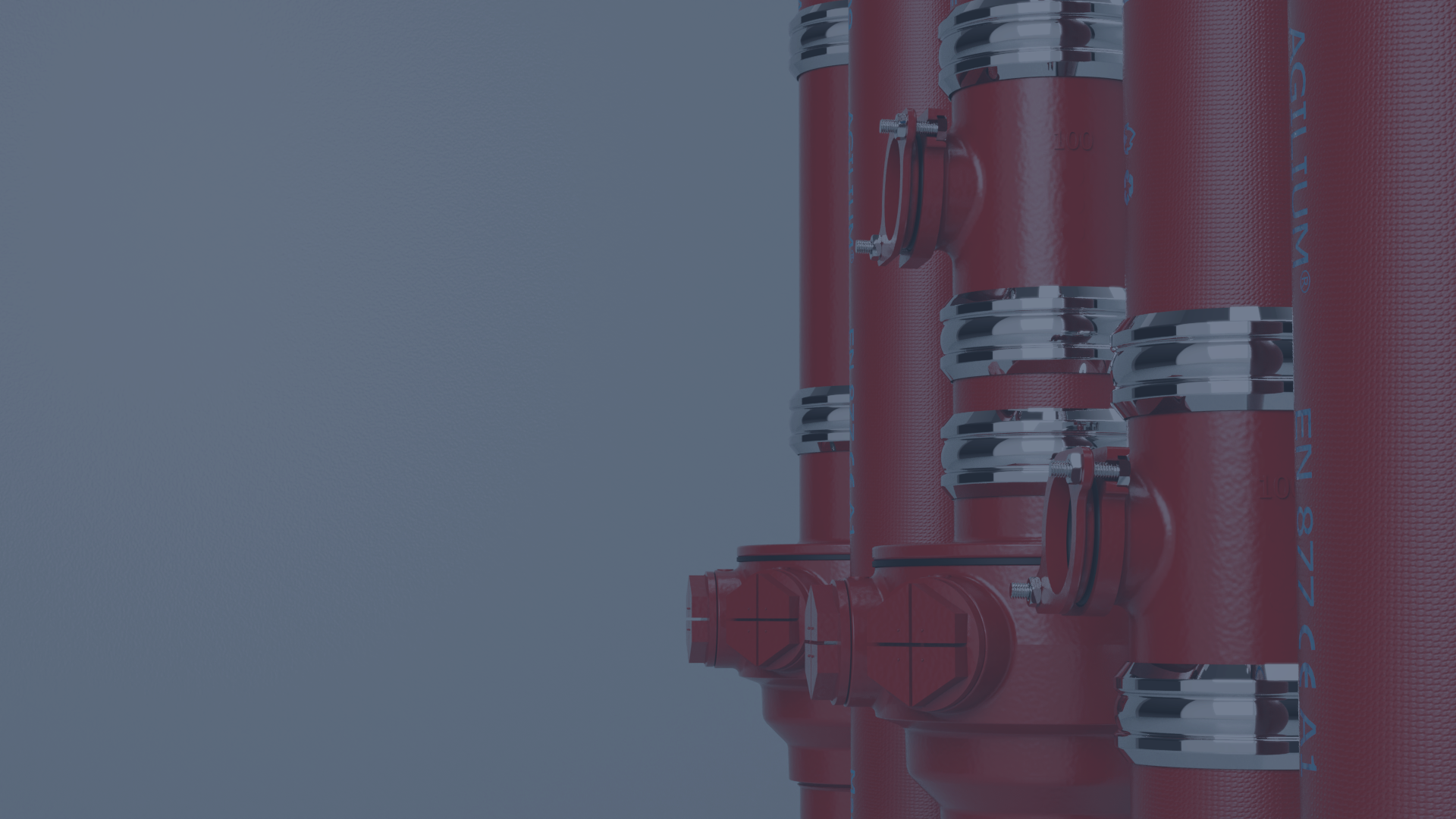

The service offers so much more than just pre-assembly

This service requires close collaboration between the complete supply chain. We will manage the process from product selection, bespoke stack design, manufacture, distribution with our partners and on-site assistance. The results will provide a reduction of time on-site with the added assurance of consistent product assembly.

On-site benefits

- Reduces on-site installation time by up to 60% > Reducing on-site labour costs

- All stacks are air tested at the factory as standard prior to dispatch

- Stacks supplied in purpose made stillages > For robust storage > For easy movements on site

- Minimal on-site wastage > No surplus products ordered > Reduced pipe cutting

- Cast iron flexibility > Connecting pipe between floors cut on site to allow for on-site variances

- Designed for one-person handling

Design benefits

- Early collaboration ensures optimised stack designs offering the best solutions

- Drawings provided for approval

- Greater level of accuracy

Material Benefits

- Cast iron pre-assembled stack solutions are fire rated to the safest level possible, A1.

- Acoustically cast iron is the quietest material on the market > May not need additional insulation

- Flexible couplings with high speed assembly > The stainless steel rapid coupling is nearly 3 times quicker than fusion welded joints in HDPE — (Luckins pricing guide)

- No concern about expansion when temperatures fluctuate > Cast iron pre-assemblies will remain straight and not bow

Saving You More Than Time

The service offers so much more than just pre-assembly

This service requires close collaboration between the complete supply chain. We will manage the process from product selection, bespoke stack design, manufacture, distribution with our partners and on-site assistance. The results will provide a reduction of time on-site with the added assurance of consistent product assembly.

On-site benefits

- Reduces on-site installation time by up to 60% > Reducing on-site labour costs

- All stacks are air tested at the factory as standard prior to dispatch

- Stacks supplied in purpose made stillages > For robust storage > For easy movements on site

- Minimal on-site wastage > No surplus products ordered > Reduced pipe cutting

- Cast iron flexibility > Connecting pipe between floors cut on site to allow for on-site variances

- Designed for one-person handling

Design benefits

- Early collaboration ensures optimised stack designs offering the best solutions

- Drawings provided for approval

- Greater level of accuracy

Material Benefits

- Cast iron pre-assembled stack solutions are fire rated to the safest level possible, A1.

- Acoustically cast iron is the quietest material on the market > May not need additional insulation

- Flexible couplings with high speed assembly > The stainless steel rapid coupling is nearly 3 times quicker than fusion welded joints in HDPE — (Luckins pricing guide)

- No concern about expansion when temperatures fluctuate > Cast iron pre-assemblies will remain straight and not bow