Sustainability

A KEY PLAYER IN THE CIRCULAR ECONOMY

More than a third of the world’s gas emissions and resource consumption can be linked to construction and the construction industry.

It is therefore necessary to significantly reduce the resource intensity of our buildings, if we want this growth to be compatible with the planet. This implies acting voluntarily both when buildings are designed and at the end of their life to ensure the waste is properly reused or recycled, and also throughout the entire life of buildings to maximise their use. Sustainable construction is a major worldwide trend.

The preservation of natural resources is a major societal challenge, especially for the construction sector, which is a major consumer of raw materials and energy. Pam Building drainage systems are a responsible and sustainable choice, respectful of natural resources and people.

A KEY PLAYER IN THE CIRCULAR ECONOMY

More than a third of the world’s gas emissions and resource consumption can be linked to construction and the construction industry.

It is therefore necessary to significantly reduce the resource intensity of our buildings, if we want this growth to be compatible with the planet. This implies acting voluntarily both when buildings are designed and at the end of their life to ensure the waste is properly reused or recycled, and also throughout the entire life of buildings to maximise their use. Sustainable construction is a major worldwide trend.

The preservation of natural resources is a major societal challenge, especially for the construction sector, which is a major consumer of raw materials and energy. Pam Building drainage systems are a responsible and sustainable choice, respectful of natural resources and people.

Ensign Agilium, our new eco-innovation

NEW generation cast iron drainage solution,

30%* lighter for easier and faster installation

20%** lower CO2e compared to our Ensign Soil range.

LESS CO2e, LIGHTER, MORE SUSTAINABLE

Ensign Agilium®: Increased ease of installation, 100% compatible with existing ranges and still as efficient.

All the characteristics you would expect of our Ensign Soil system, with extra installation & environmental benefits

Ensign Agilium, our new eco-innovation

NEW generation cast iron drainage solution,

30%* lighter for easier and faster installation

20%** lower CO2e compared to our Ensign Soil range.

LESS CO2e, LIGHTER, MORE SUSTAINABLE

Ensign Agilium®: Increased ease of installation, 100% compatible with existing ranges and still as efficient.

All the characteristics you would expect of our Ensign Soil system, with extra installation & environmental benefits

A cast iron pipe gives our waste a second life

In order to contribute to the preservation of natural resources, our melt is produced by recycling cast iron and ferrous products. Unlike plastics, it can be completely and systematically recycled at the end of its life.

Pam Building pipe systems can be recycled without any deterioration of their properties. Owing to the stability of their mechanical properties, the service life of our cast iron pipe systems is currently considered to be twice that of alternative products made of plastic materials.

100% recyclable indefinitely without losing any of its properties and made from recycled content*

For the standard Ensign Soil range, recycled content is 99% with 11.5% pre-consumer** & 87.5% post-consumer*** according to ISO 14021: 1999.

Nothing is wasted: everything is recycled

Cast iron pipe systems are based on the principle of modular ranges of removable components. Their mechanical assemblies are reversible.

You can change your mind today or even tomorrow. When pipe systems are disassembled or modified, these components can be reused, which cuts down on waste dumping.

*Recycled content: proportion, by mass, of recycled material in a product or packaging. Only pre-consumer and post-consumer materials shall be considered recycled content.

** Pre-consumer material: material diverted from the waste stream during a manufacturing process. This excludes the reuse of materials such as rework, regrind, or scrap generated in a process and capable of being reclaimed within the same process that generated it.

*** Post-consumer material: material generated by households or commercial, industrial and institutional facilities in their role as end users of the product which can no longer be used for its intended purpose.

100% recyclable indefinitely without losing any of its properties and made from recycled content*

For the standard Ensign Soil range, recycled content is 99% with 11.5% pre-consumer** & 87.5% post-consumer*** according to ISO 14021: 1999.

Nothing is wasted: everything is recycled

Cast iron pipe systems are based on the principle of modular ranges of removable components. Their mechanical assemblies are reversible.

You can change your mind today or even tomorrow. When pipe systems are disassembled or modified, these components can be reused, which cuts down on waste dumping.

*Recycled content: proportion, by mass, of recycled material in a product or packaging. Only pre-consumer and post-consumer materials shall be considered recycled content.

** Pre-consumer material: material diverted from the waste stream during a manufacturing process. This excludes the reuse of materials such as rework, regrind, or scrap generated in a process and capable of being reclaimed within the same process that generated it.

*** Post-consumer material: material generated by households or commercial, industrial and institutional facilities in their role as end users of the product which can no longer be used for its intended purpose.

Discover how Pam Building's solutions can contribute to the international labels

The product’s life cycle is also first-class in terms of environmentally-friendly logistics, long-lasting functionality (up to 70 years without compromising the mechanical properties), low maintenance costs and worthwhile recycling.

Protecting the environment means understanding our products’ complete life cycle which helps us focus on areas for improvement, so we can significantly reduce our impact on the environment. This is the main route through which we can have a positive impact.

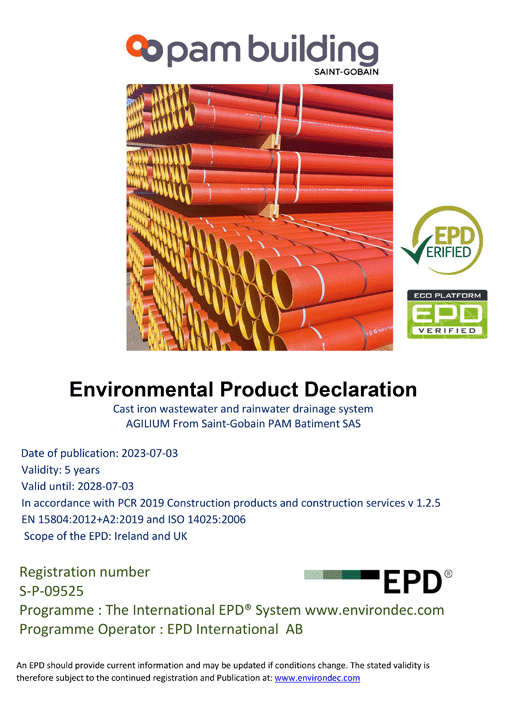

Environmental Product Declaration

To help customers make a better-informed choice, in 2019 we published an updated Environmental Product Declaration for our standard wastewater and rainwater ranges.

In response to a worldwide need for harmonization, international standard ISO 21930 provides the principles and requirements for the Environmental Product Declarations (EPD) of building products. This standard uses the complete life cycle of products «from the cradle to the grave” as the relevant analysis.

As the French standard was even more stringent, the decision was made to keep this information model as described in French standard NF P 01-010: an objective analysis of the life cycle “from the cradle to the grave” and energy consumption with reference to a functional unit (FU)* and a lifetime of 70 years.

We routinely adopt Eco-Design and Eco-Innovation principles which extend to including a sustainable and responsible approach to our procurement policies and how we manage, measure and reduce our carbon emissions.

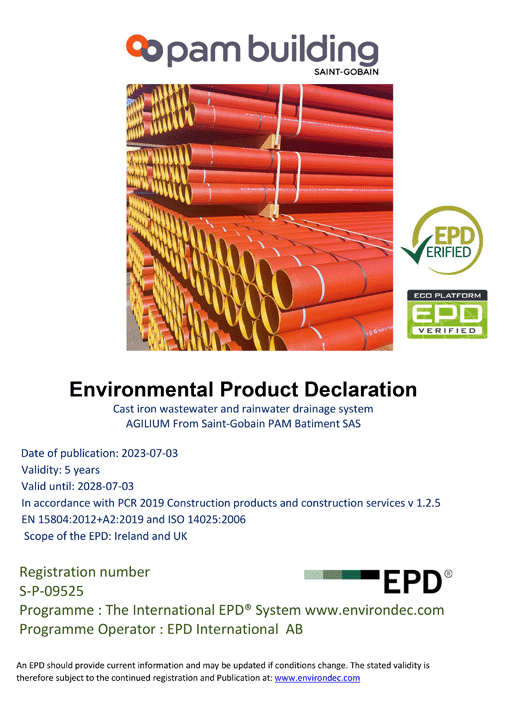

Environmental Product Declaration

To help customers make a better-informed choice, in 2019 we published an updated Environmental Product Declaration for our standard wastewater and rainwater ranges.

In response to a worldwide need for harmonization, international standard ISO 21930 provides the principles and requirements for the Environmental Product Declarations (EPD) of building products. This standard uses the complete life cycle of products «from the cradle to the grave” as the relevant analysis.

As the French standard was even more stringent, the decision was made to keep this information model as described in French standard NF P 01-010: an objective analysis of the life cycle “from the cradle to the grave” and energy consumption with reference to a functional unit (FU)* and a lifetime of 70 years.

We routinely adopt Eco-Design and Eco-Innovation principles which extend to including a sustainable and responsible approach to our procurement policies and how we manage, measure and reduce our carbon emissions.

A manufacturer’s commitment: protect the environment

For Pam Building, being committed to sustainable development actions by ensuring its plants’ full compliance with current regulations is just the start.

Plants in the metallurgical industry call for greater vigilance and strict compliance with instructions, as the risks of serious accidents are particularly high.

Key figures:

- > At our Telford plant we have zero production waste to landfill.

- > A 70% reduction in water consumption at our Bayard plant since 2001

- > Objective to reduce our carbon emissions by 15% by 2025.

A manufacturer’s commitment: protect the environment

For Pam Building, being committed to sustainable development actions by ensuring its plants’ full compliance with current regulations is just the start.

Plants in the metallurgical industry call for greater vigilance and strict compliance with instructions, as the risks of serious accidents are particularly high.

Key figures:

- > At our Telford plant we have zero production waste to landfill.

- > A 70% reduction in water consumption at our Bayard plant since 2001

- > Objective to reduce our carbon emissions by 15% by 2025.