Tel: 01952 262 529

CHEMICAL AND CORROSION RESISTANCE

CHEMICAL RESISTANCE OF THE OCHRE PIPE COATING

The Ensign pipes are internally lined with a two-part epoxy to provide chemical resistance which exceeds the requirements stipulated in the new European standard BS EN 877 which includes pH2 – pH12 (with exception of some organic acids).

The epoxy coating on the fittings matches the performance of the pipes.

Chemical Resistance

The constraints on sanitary drainage systems are constantly increasing

To test chemical resistance of cast iron products, according to standard EN 877, the product samples are tested for 30 days at a temperature of 23 3°C with the following liquids (pH constantly monitored):

- A solution of sulphuric acid with a pH of 2

- A solution of sodium hydroxide with a pH of 12

- A solution of wastewater with a pH of 7

Resistance to hot water (24 h at a continuous 95°C) and thermal cycles (1,500 cycles of 5 min between 15°C and 93°C) are also tested according to standard EN 877.

To provide clearer guidance on the chemical resistance of the Ensign above and below ground applications, we have carried out 20 further tests in addition to the requirements of standard EN 877 on commonly-used detergent products (floor cleaning products, laundry detergents, etc.) and special products (stain removers, drain cleaners, etc.).

The tests were carried out on samples, under the temperature of use recommended by the manufacturers and, where relevant, up to 70°C since hot water is normally supplied in houses at around 50–60°C. After stopping the test, the pipes and fittings were washed immediately to eliminate any stains, and the coatings were examined for blistering and rusting according to ISO 4628-2 and 3. (Accepted levels according to EN 877).

The duration of the test is considered equivalent to the extrapolation of real chemical stress undergone for 7 or 10 years (10 to 15 min of stress per day). This test method, however, simulates severe stress since the samples lie in direct contact with the solution, the temperature is maintained and the test includes no rinsing for its duration.

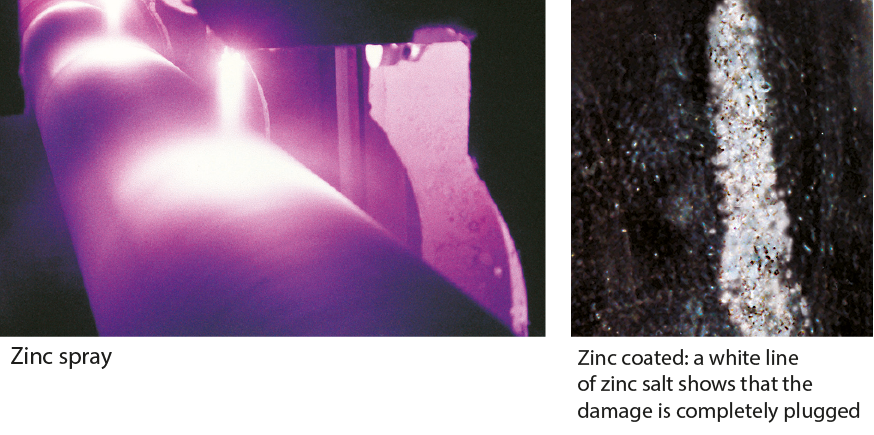

BELOW GROUND RANGE – ZINC COATED FOR A REASON

The zinc metal coating gives an active protection layer providing a galvanic action of a zinc-iron cell. This action is two-fold:

- Formation of a stable protective layer of insoluble zinc salts

- Self-repairing of any damage.

Zinc metalisation is an excellent corrosion inhibitor and is extremely effective at extending the lifespan of products subject to backfill or climatic stresses.

BELOW GROUND RANGE COUPLINGS

Buried systems are subjected to ground loadings which can cause shearing strain on couplings. For these applications, it is therefore recommended to use wider couplings and to use the “all stainless steel version” of the steel couplings to avoid corrosion due to the aggressiveness of the ground.

Please contact our Technical Sales team for further advice on these topics.

BELOW GROUND RANGE COUPLINGS

Buried systems are subjected to ground loadings which can cause shearing strain on couplings. For these applications, it is therefore recommended to use wider couplings and to use the “all stainless steel version” of the steel couplings to avoid corrosion due to the aggressiveness of the ground.

Please contact our Technical Sales team for further advice on these topics.